Fertilizer Production Line

Fertilizer Production Line/Bulk Blending Fertilizer Production Line

Bulk Blending Fertilizer Production Line

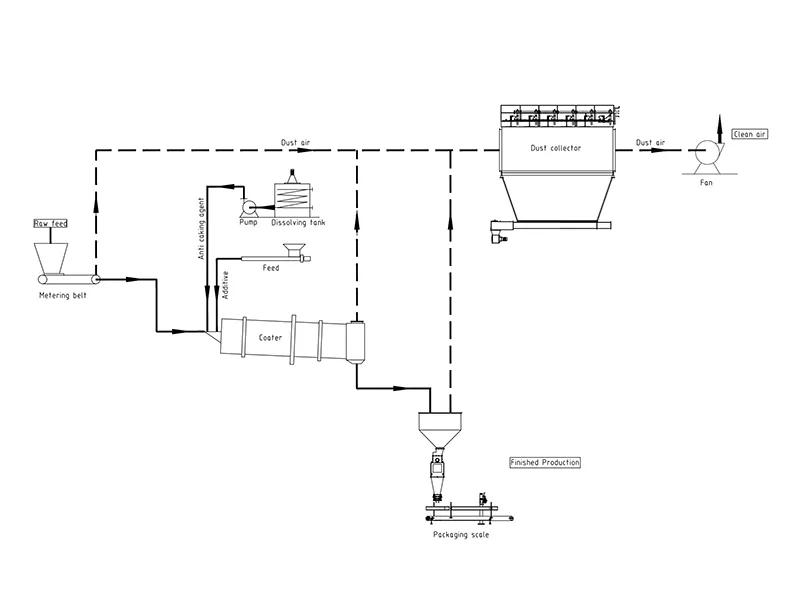

The bulk blending process, also known as the BB fertilizer production process, involves transporting raw materials like nitrogen, phosphorus, potassium, and fillers to separate storage bins. After being precisely weighed using automated metering systems, the materials are transferred to a pre-mixing conveyor and then into a horizontal BB fertilizer mixer, which can operate in either batch or continuous modes. Inside the mixer, the granules are thoroughly combined, creating a uniform mixture. The blended fertilizer is then moved to the finished product bins, where it is weighed, packaged, and prepared for storage. This process is particularly valued for its efficiency in producing fertilizers tailored to specific crop and soil needs, making it a versatile solution in modern agriculture.

Process Features

- The bulk blending fertilizer production process stands out for its high production capacity, requiring low investment and minimal space. The production line includes four key components: an automatic batching system, elevator, mixer, and automatic packaging equipment.

- This fertilizer production method is efficient, with a simple setup that leads to low equipment costs and low processing expenses. It’s a practical solution that can be easily scaled for different production capacities.

- With a simple and streamlined production line, the maintenance costs are low, and only 3 to 5 workers are needed per shift, making it an efficient option for fertilizer production.

Factors Affecting the Bulk Blending Process

When different base fertilizers are mixed, certain reactions can lower the critical relative humidity (CRH), which may cause the product to absorb moisture and form clumps. To prevent this from happening, it is necessary to ensure that the granules used in the process have consistent size, density, and roundness. This consistency helps avoid issues like clumping, crushing, or a low moisture absorption point during production, storage, and use. Research has shown that the absorption rates of PO (phosphorus oxide) and KO (potassium oxide) in uniform fertilizers differ significantly from those in bulk-blended fertilizers (with absorption rates being 6 times and 4.6 times faster, respectively). This difference can lead to slight variations in fertilizer effectiveness.

Additionally, in China, the widespread adoption of soil testing and fertilizer recommendations is still limited, which means that BB fertilizers have yet to gain full recognition and acceptance among farmers. As a result, the application of this method faces certain limitations in the current market.

Other Fertilizer Production Lines

Contact us now

To Learn About Our Fertilizer Production Lines

Mobil/Whatsapp

086-17715506502

karen@yrcexport.cn