Fertilizer Production Line

Fertilizer Production Line/ Tower Mixed Fertilizer Production Line

Tower Mixed Fertilizer Production Line

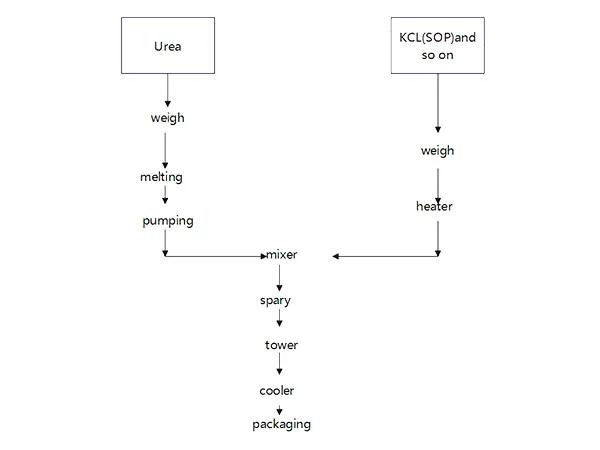

Tower blending is a widely used process for producing compound fertilizers through a molten-state system. Solid urea or ammonium nitrate is heated until it melts, or molten urea can be used directly after concentration. Phosphate, potash, fillers, and additives are then blended into this molten slurry. The slurry is sent into the blending tower, where it is sprayed down from the top of the tower. As it descends, the slurry interacts with rising gases, allowing for efficient heat exchange. During this process, the granules form while cooling down, resulting in smooth and durable fertilizer pellets. Once the granules reach the bottom of the tower, they are screened and surface-treated, ensuring high-quality compound fertilizers that are ready for use.

- Daily production capacity: 300-500 tons/day

Advantages

- By utilizing molten urea or ammonium nitrate directly, the system eliminates the need for extra steps like solid urea granulation, packaging, and crushing, enhancing the production flow.

- The natural heat from the molten materials minimizes moisture content, negating the need for a drying stage and thus significantly reducing energy consumption.

- The resulting fertilizer granules are round, smooth, and uniform, with a moisture content of less than 1% and a compressive strength above 30N, ensuring durability and preventing caking during storage.

- The process yields a high percentage of perfectly formed granules, resulting in minimal waste and recirculation during production.

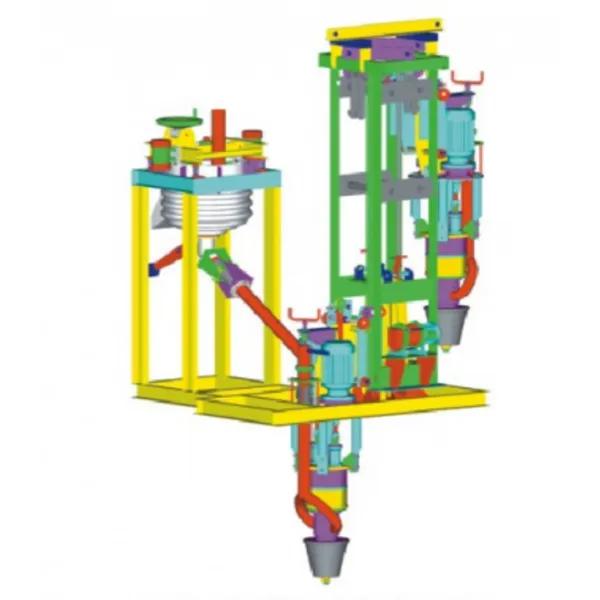

Main Equipment

- High tower which is typically constructed from cement; steel towers are rarely built due to their shorter lifespan

- Melting tank

- Rotary granulator

- Bucket elevator

- Cooler

- Packaging machine

Other Fertilizer Production Lines

Contact us now

To Learn About Our Fertilizer Production Lines

Mobil/Whatsapp

086-17715506502

karen@yrcexport.cn