Playlist

3 Videos

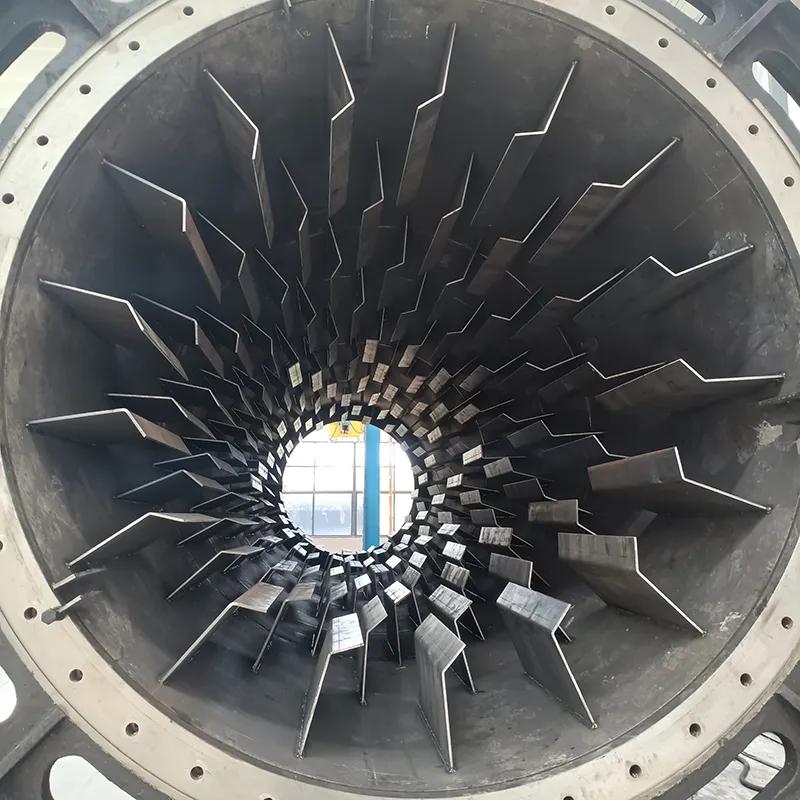

ROTARY DRYER

The rotary dryer operates by introducing heated air while the inclined drum continuously rotates, allowing wet materials to move forward and exchange heat effectively with the air. Widely used in agriculture, chemicals, and mining, it caters to various production scales and material types.

Features

- Constructed with a high-precision ground base, offering high concentricity and reduced wear, resulting in longer operational life.

- The drum features flange connections, ensuring precise alignment and easy maintenance or replacement.

- Critical components like the gear ring, rolling rings, and support rollers are crafted from high-quality cast steel for improved wear resistance and longevity.

- Internally, the layout of the lifting plates is optimized for spacing and angle, enhancing heat efficiency while considering the material’s specific properties.

- Equipped with external hammering devices to prevent materials from sticking to the drum walls effectively.

SPECIFICATIONS

| Drum size (m) | Drum | Production capacity (t/h) | Flow direction | Reducer | Motor | Dimensions (L×W×H) (mm) | Weight (t) | |||||

| Inner diameter (mm) | Length (mm) | Inclination (°) | Rev. (r/min) | Model | Ratio | Model | Power (kW) | |||||

| Ø1.2×10 | 1200 | 10000 | 2.5 | 6.1 | 1-1.5 | Downstream | JZQ500 | 31.50 | Y160M-6 | 7.5 | 10000×2280×2245 | 13.0 |

| Ø1.5×14 | 1500 | 14000 | 2.5 | 4.28 | 3-4 | ZQ650 | 31.50 | Y200L-6 | 18.5 | 15750×3085×3180 | 21.0 | |

| Ø1.6×16 | 1600 | 16000 | 2.5 | 5 | 4-5 | ZQ650 | 23.34 | Y200L1-6 | 18.5 | 17500×3232×3500 | 26.0 | |

| Ø1.8×18 | 1800 | 18000 | 2.5 | 5 | 5-7 | ZQ650 | 23.34 | Y200L1-6 | 18.5 | 19614×3438×3673 | 30.0 | |

| Ø2.0×20 | 2000 | 20000 | 2.5 | 6 | 7-10 | ZL65 | 22.50 | Y225M-6 | 30 | 22091×3232×4445 | 43.0 | |

| Ø2.2×22 | 2200 | 22000 | 2.5 | 3.29 | 8-14 | ZL65 | 40.00 | Y250M-6 | 37 | 23400×4593×3810 | 50.0 | |

| Ø2.4×24 | 2400 | 24000 | 2.5 | 2.82 | 12-16 | ZL75 | 45.00 | Y280S-6 | 45 | 25630×4097×5932 | 70.0 | |

| Ø2.6×26 | 2600 | 26000 | 2.5 | 3.8 | 20-25 | ZL100 | 35.50 | Y280M-6 | 55 | 27750×3100×5810 | 84.0 | |

| Ø2.8×28 | 2800 | 28000 | 2.5 | 2.66 | 18-20 | ZL115 | 45.00 | Y280S-6 | 75 | 29630×4220×5110 | 100.0 | |

| Ø2.8×34 | 2800 | 34000 | 2.5 | 2.65 | 18-20 | ZL115 | 45.00 | Y315M-6 | 110 | 37500×4050×5350 | 111.0 | |

| Ø3.0×28 | 3000 | 28000 | 2.5 | 3.96 | 20-22 | ZSY450 | 45.00 | Y315M1-4 | 132 | 30615×5960×6450 | 130.0 | |

| Ø3.2×25 | 3200 | 25000 | 2.5 | 4.0 | 20-30 | ZSY450 | 45.00 | Y315M-4 | 185 | 29500×6500×6300 | 138.0 | |

| Ø3.4×34 | 3400 | 34000 | 1.8 | 2.56 | 20-30 | ZL130 | 45.00 | Y2-355M2-6 | 200 | 34600×6678×6540 | 175.0 | |

| Ø3.6×34 | 3600 | 34000 | 1.8 | 2.51 | 30-40 | ZL130 | 40.00 | YKK3554-4 | 250 | 34600×6890×6540 | 209.0 | |

| Ø4.0×34 | 4000 | 34000 | 1.8 | 2.09 | 40-45 | ZSY630 | 90.00 | YKK4003-4 | 315 | 36466×7800×6800 | 232.0 | |

| Ø4.2×34 | 4200 | 34000 | 2.5 | 2.15 | 42 | ZSY630 | 80.00 | YKK4005-4 | 400 | 37466×8000×6800 | 250.0 | |

| Ø4.5×34 | 4500 | 34000 | 1.8 | 1.85 | 160 | ZSY630 | 80.00 | YKK4502-4 | 500 | 38000×8300×7200 | 290.0 | |

FAQ

What are the main stages in fertilizer production?

Drum granulation:

- Gathering raw materials such as nitrogen, phosphorus, potassium, and other essential minerals

- Mixing and blending the materials thorough

- Heating and processing the mixture to form granules

- Drying and cooling the granulated product to prepare for packaging

Extrusion granulation:

- Drying the raw mixture and grinding it into a fine powder

- Pressing the powder into granules

- Screening the granules to ensure uniformity

What challenges do fertilizer manufacturers typically face?

Fertilizer manufacturers often deal with issues related to quality control, production costs, environmental regulations, and supply chain management. With extensive experience in the industry, we provide practical solutions to help address these challenges and ensure efficient production.

Related Products

Contact us now

To Learn About Our Fertilizer Production Lines

Mobil/Whatsapp

086-17715506502

karen@yrcexport.cn

Get in Touch

Fertilizer Production Equipment

One Stop Solutions for Your Fertilizer Production Plant

Compound Fertilizer Production Line

Fertilizer granulation solution for NPK compound fertilizers

Bulk Blending Fertilizer Production Line

Fertilizer production solution for BB fertilizers (bulk blend NPK fertilizers)

Compacted Fertilizer Production Line

Fertilizer granulation solution with dry compaction process