Belt Weigher

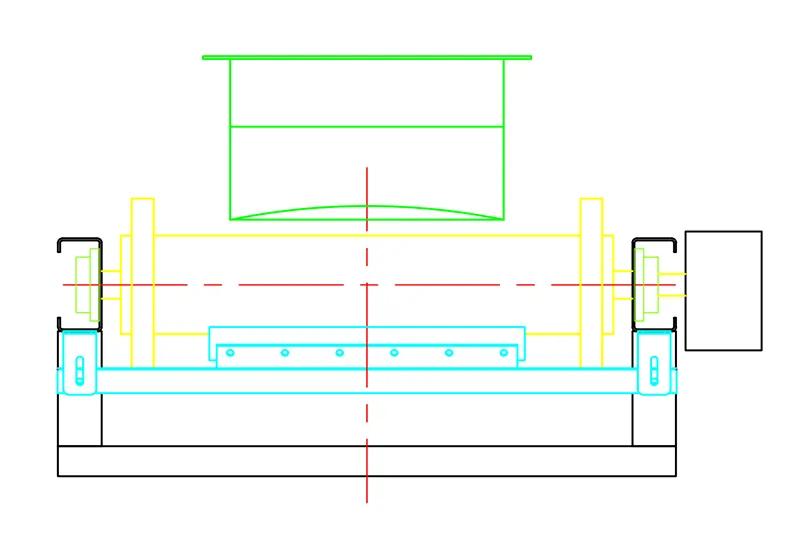

Belt weigher systems offer an efficient solution for accurately weighing bulk materials as they move along a conveyor belt. The system consists of a belt conveyor, load cells for weight detection, and a variable frequency drive that ensures precise material flow control. It operates by continuously comparing the actual flow of material with a preset target value. Based on this comparison, the system adjusts the conveyor speed through the variable frequency drive ensuring the required flow rate is maintained. This makes it an excellent tool for industries requiring automated material feeding and weighing control.

Working Principle

- Weight detection: Materials passing over the belt are measured using load cells for weight accuracy.

- Flow rate adjustment: A controller monitors the material flow, comparing it with the target rate.

- Speed control: The controller adjusts the belt speed through the VFD to meet the required feed rate.

Advantages

- Simple and convenient to operate, just load the material, start the system, and it will automatically weigh and regulate the feed.

- Ensures precise and consistent material flow, improving operational efficiency and reducing waste.

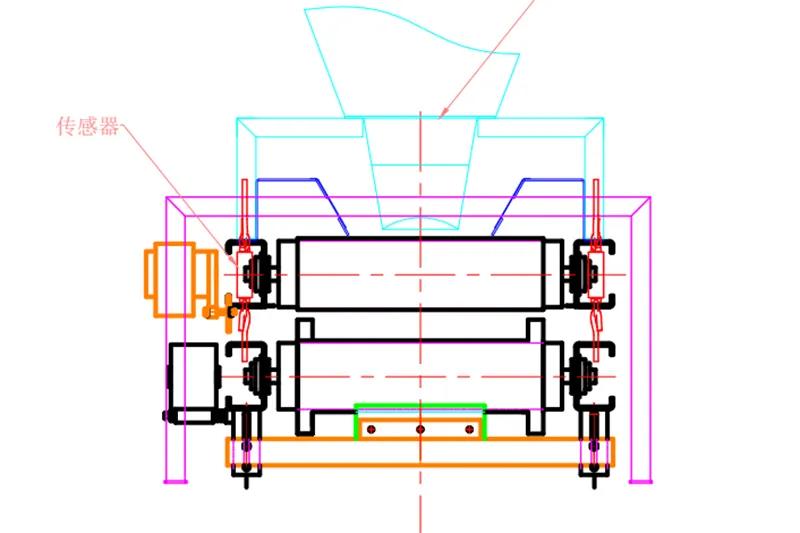

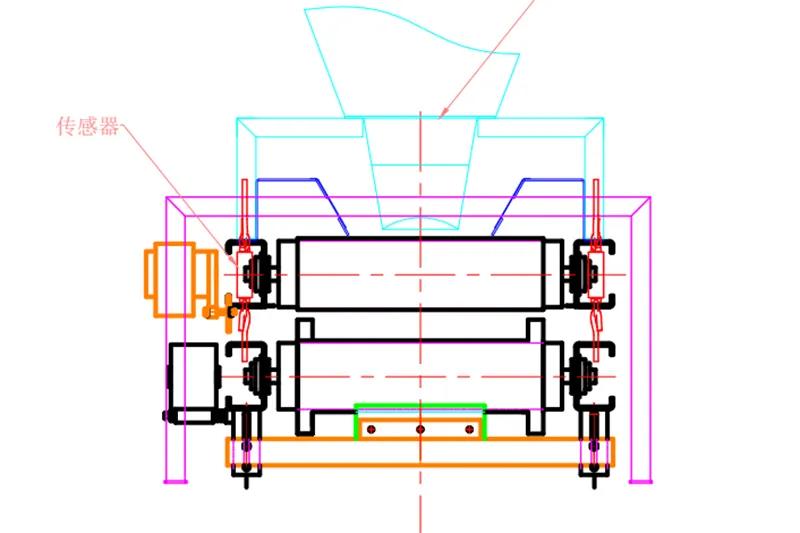

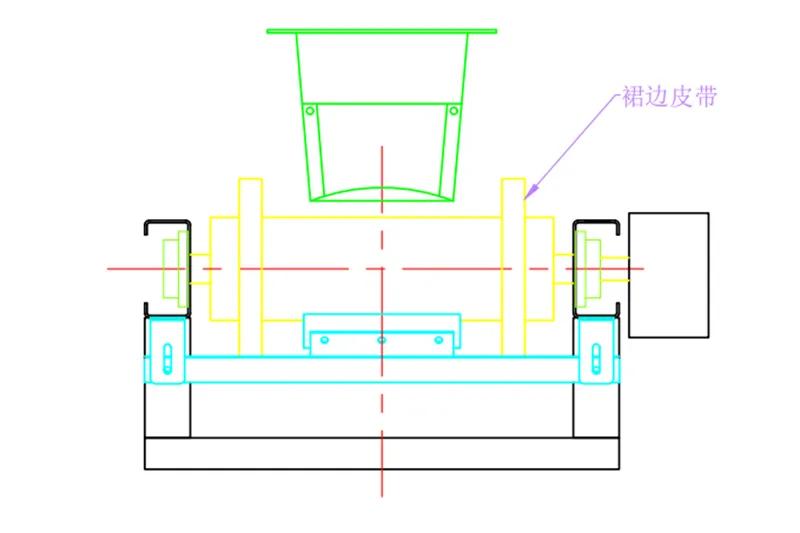

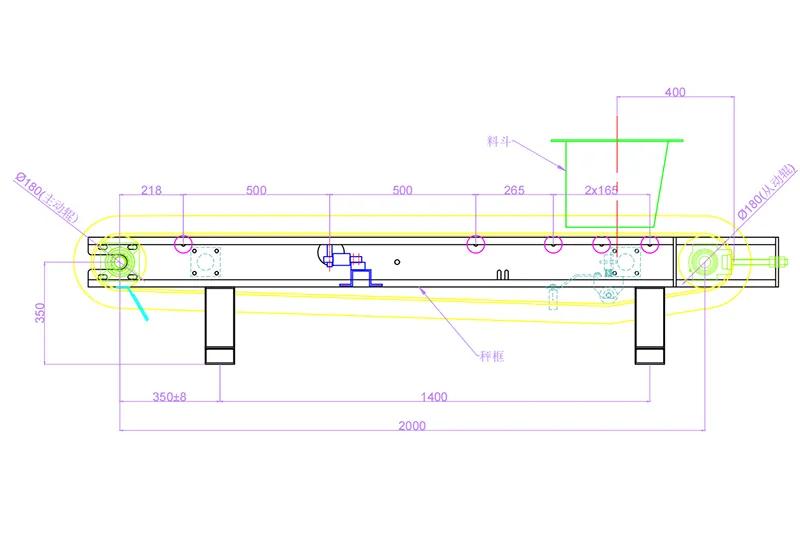

B500 Double Belt Weigher

| Model | B500*2000 |

| Voltage | AC380V |

| Power | 1.1kW+1.1kW |

| Weighing accuracy | ±0.5% |

| Capacity | 0.5-6t/h |

| Reducer speed ratio | 156 |

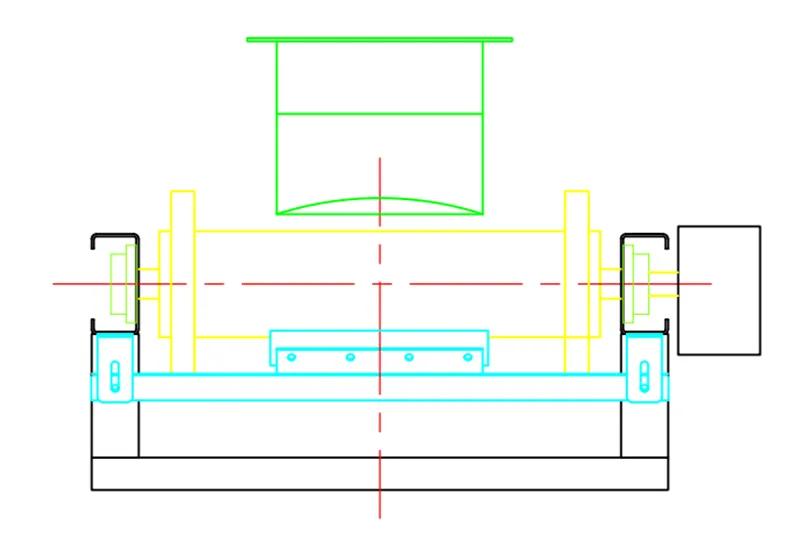

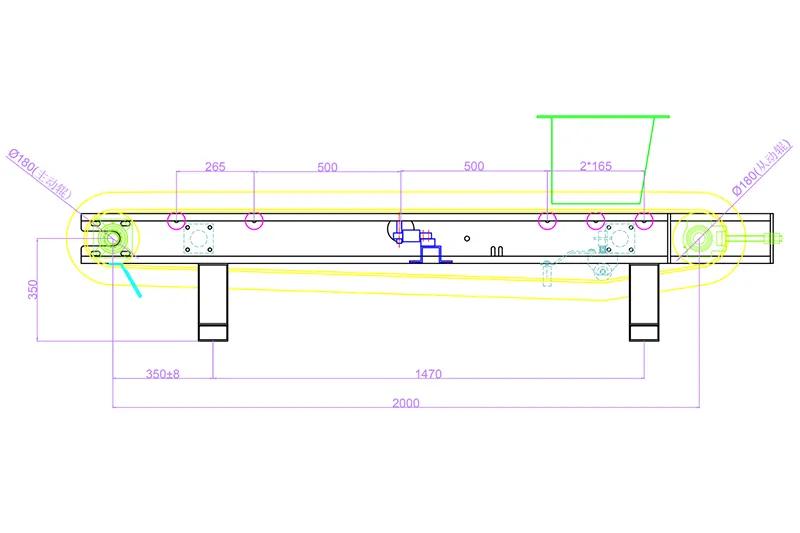

B650 Double Belt Weigher

| Model | B650*2000 |

| Voltage | AC380V |

| Power | 1.1kW+1.1kW |

| Weighing accuracy | ±0.5% |

| Capacity | 1-8t/h |

| Reducer speed ratio | 189 |

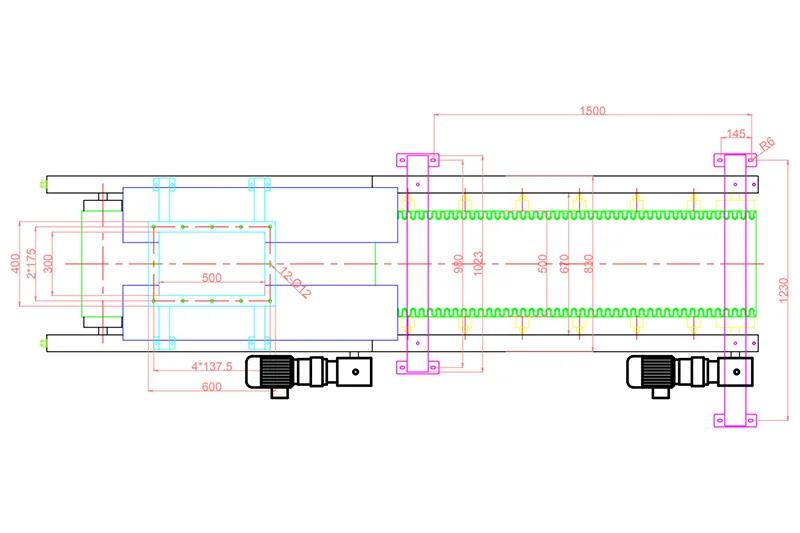

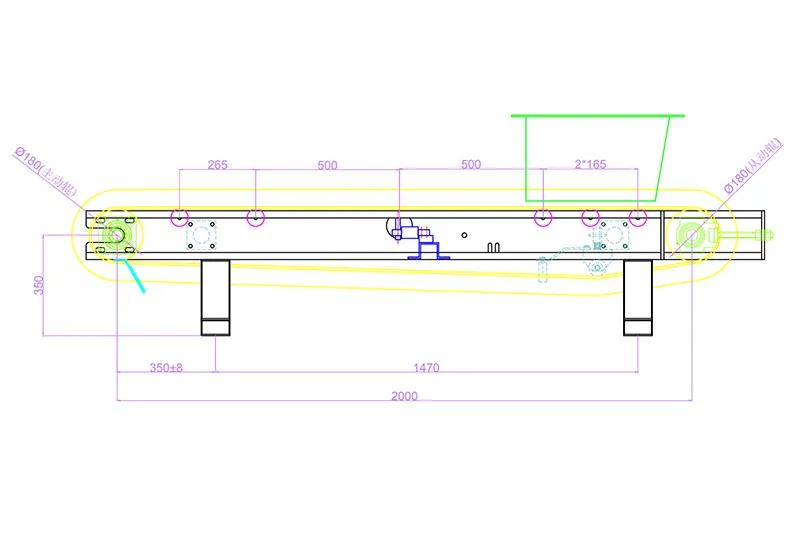

B500 Single Belt Weigher

| Model | B500*2000 |

| Voltage | AC380V |

| Power | 1.1kW |

| Weighing accuracy | ±0.5% |

| Capacity | 0.5-5t/h |

| Reducer speed ratio | 188 |

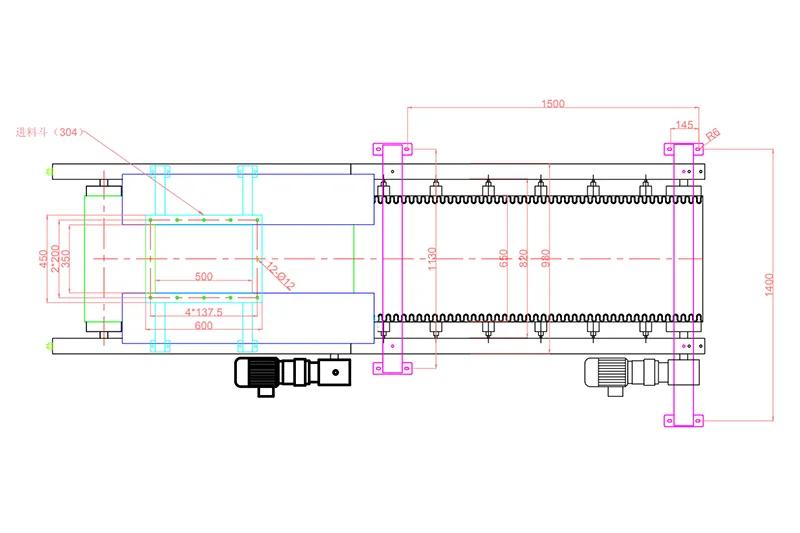

B650 Single Belt Weigher

| Model | B650*2000 |

| Voltage | AC380V |

| Power | 1.1kW |

| Weighing accuracy | ±0.5% |

| Capacity | 1-8t/h |

| Reducer speed ratio | 189 |

B800 Single Belt Weigher

| Model | B800*2000 |

| Voltage | AC380V |

| Power | 2.2kW |

| Weighing accuracy | ±0.5% |

| Capacity | 2-20t/h |

| Reducer speed ratio | 68 |

FAQ

What equipment is typically included in a fertilizer production line?

A complete fertilizer production line, whether for organic or compound fertilizers, usually features equipment for mixing, crushing, screening, granulation, cooling, and coating. Each machine plays a key role in ensuring efficient production and high-quality outputs.

What raw materials are commonly used in compound fertilizer production?

To produce various types and concentrations of compound fertilizers, manufacturers commonly mix materials like urea, ammonium chloride, MAP (monoammonium phosphate), DAP (diammonium phosphate), MOP (muriate of potash), and SOP (sulfate of potash). These materials help achieve the desired nutrient balance for different crops.

Related Products

Contact us now

To Learn About Our Fertilizer Production Lines

Mobil/Whatsapp

086-17715506502

karen@yrcexport.cn