Fertilizer Production Line

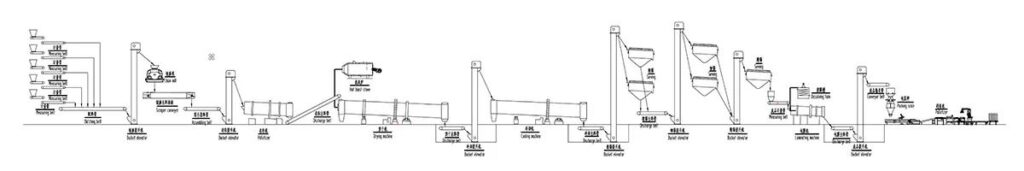

Fertilizer Production Line/ Compound Fertilizer Production Line

Compound Fertilizer Production Line

The compaction granulation process is a dry granulation method in which premixed materials are fed between two counter-rotating rollers. Under strong pressure, the material is compacted into solid sheets. These sheets are then crushed and screened to form fertilizer granules of the desired size. This process is commonly used to produce fertilizers such as rare earth elements, ammonium bicarbonate, ammonium chloride, ammonium sulfate and dibasic nitrogen and potassium fertilizers.

Process Features

- The wet granulation process uses widely available and easily sourced raw materials. It is a simple and cost-effective process, requiring low investment and offering flexible production.

- Adjusting the nutrient content of the final product is easy and versatile, making the process adaptable to different fertilizer formulations.

- The process relies on solid raw materials, making it less dependent on specific raw material supplies.

- As a secondary processing method for base fertilizers, it results in minimal environmental impact.

Factors that Affect the Fertilizer Granulation Process

Several factors influence the quality and efficiency of the granulation process for compound fertilizers. These include the production technology, equipment used, the physical and chemical properties of raw materials and additives, the production formula, as well as operational conditions such as the temperature and airflow in the dryer, the material temperature, liquid phase, material flow rate, return material ratio, operator skills, and even climatic conditions. Considering all these elements is essential to achieving high-quality, efficient production.

Contact us now

To Learn About Our Fertilizer Production Lines

Mobil/Whatsapp

086-17715506502

13915479447