Equipment

Organic and Compound Fertilizer Manufacturing Equipment

Our company specializes in the production of fertilizer equipment, which is primarily designed to handle granular and powder materials. This fertilizer processing equipment, including granulators, dryers, coolers, coating machines, crushers, mixers, blenders, elevators, conveyors, screening machines, and ball mills, is widely used in the production of compound fertilizers, bio-organic fertilizers, water-soluble fertilizers, BB fertilizers, and potassium sulfate production lines.

Additionally, these machines can be applied in industries that require the processing of similar granular materials, extending their usability beyond fertilizer production.

Granulators are an important in fertilizer production lines, transforming loose powdery raw materials into uniform granules through processes such as mixing, pressing, and shaping.

Breaking down large raw materials into smaller, manageable particles is an important process in fertilizer production. Crushers are designed for this purpose, ensuring that raw materials are properly prepared for further processing.

Ideal for high-capacity industrial operations, the double-shaft paddle mixer blends materials by using two synchronized rotating shafts equipped with paddles.

These drying machines use heat generated from coal or natural gas, which is then circulated through the dryer by fans to remove moisture from the material quickly.

Bucket elevators and conveyors are equipment that is widely used for efficiently transporting and lifting materials in fertilizer production.

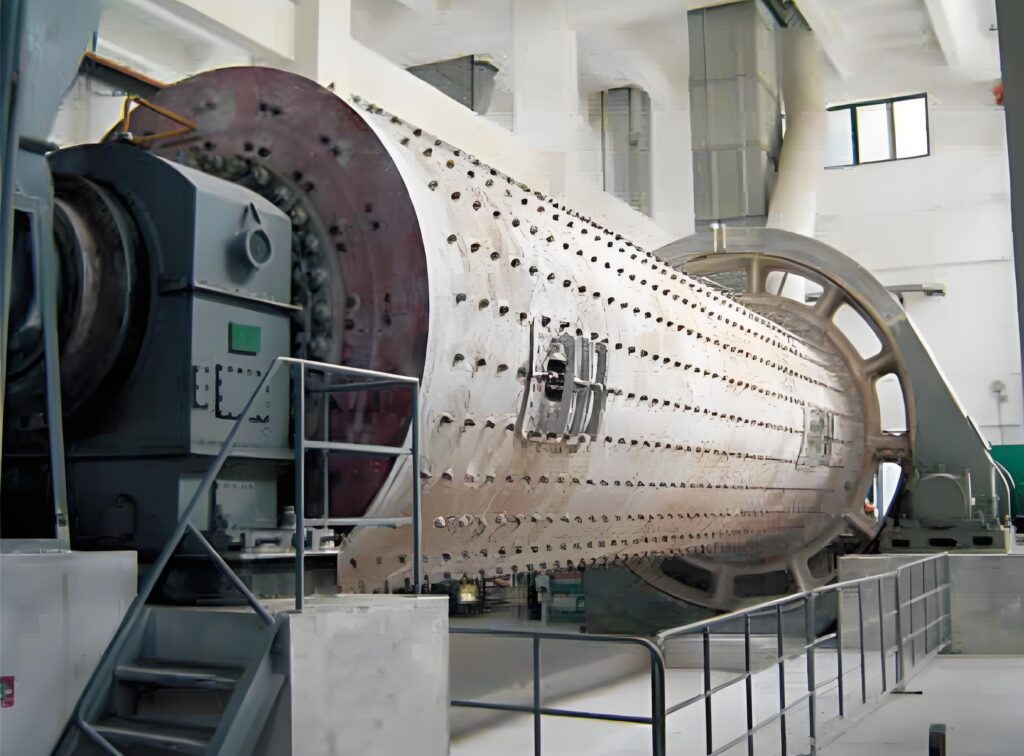

A ball mill is a powerful piece of equipment designed to break down large, hard materials into fine particles or powder. Using internal grinding media, the ball mill applies continuous impact to crush the material until it reaches the desired fineness.

Screening machines are used for grading and sorting particles based on their size, playing a crucial role in industries such as fertilizer production, mining, and metallurgy

The coating equipment plays an important role in fertilizer production, specifically designed to enhance the final quality of fertilizers. After the cooling process, it gives fertilizers a polished, rounded shape while applying a thin oil-based coating.

Auxiliary equipment is also important in in fertilizer production, supporting processes like transportation, screening, drying, and coating. Learn more about our fertilizer auxiliary machinery that enhances efficiency and ensures smooth production operations.

FAQ

What equipment is typically used for organic fertilizer production?

In fertilizer manufacturing, common equipment includes fermentation machines, crushers, mixing equipment, screening machines, granulators, and drying equipment. These machines work together to process organic materials and create high-quality organic fertilizers.

What are the different manufacturing processes for organic and compound fertilizers?

- For organic fertilizer, the process usually starts with aerobic fermentation using either a compost turner or a fermentation tank. After fermentation, the raw materials are crushed, followed by granulation, drying, and cooling.

- For compound fertilizer, the raw materials are first measured and mixed in the correct proportions before crushing. Then, the process moves through granulation, drying, cooling, and other steps to create the final fertilizer product.

Looking for Equipment or a Solution for Your Fertilizer Plant?

Our specialists are ready to provide tailored information on our range of fertilizer production machinery and how it can fit your needs. Let’s discuss how we can assist with your project.

karen@yrcexport.cn

Mobil/Whatsapp

086-17715506502

Fertilizer Production Line

Our advanced facilities are equipped with large-scale processing equipment, which allow us to produce high-quality fertilizer production machines that meet the unique needs of each customer.