Fertilizer Production Line

Fertilizer Production Line/ Compacted Fertilizer Production Line

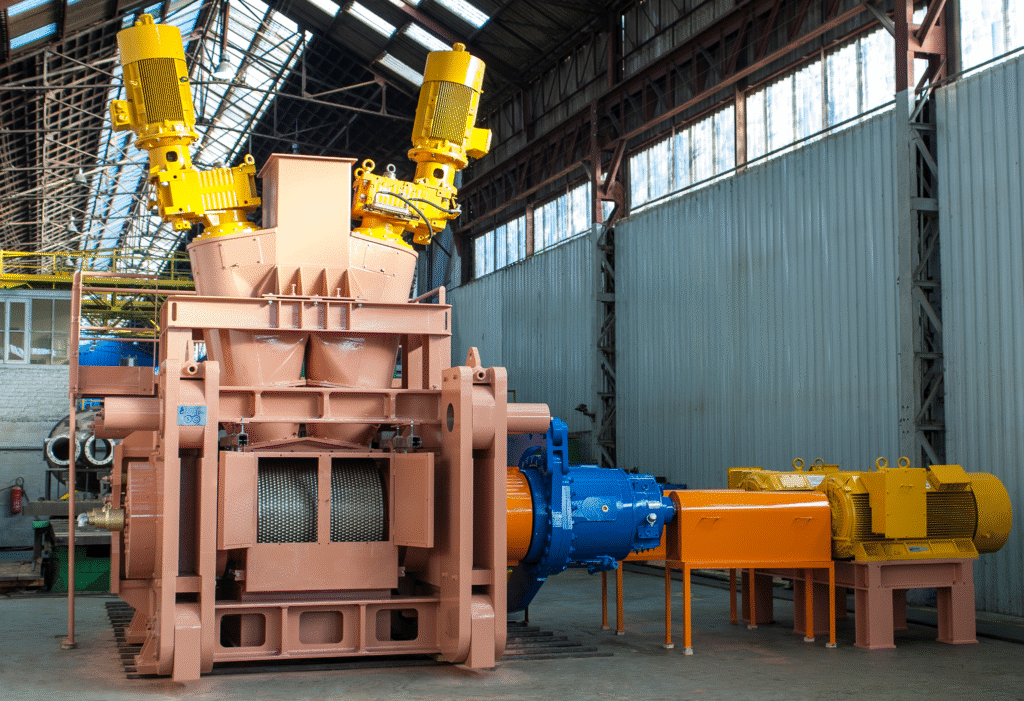

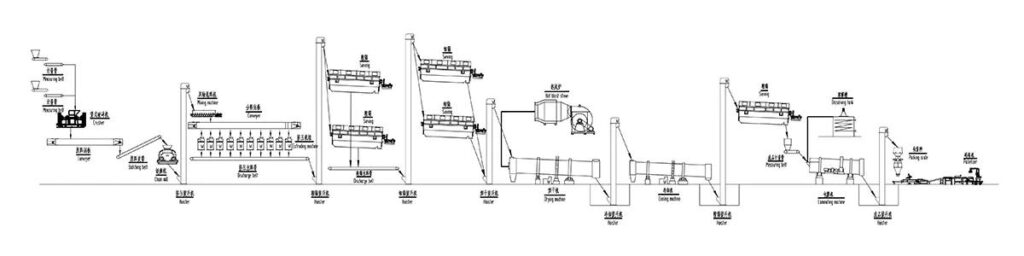

Compacted Fertilizer Production Line

The compaction granulation process is a dry granulation method where pre-mixed materials are fed between two rollers rotating in opposite directions. Under the force of intense pressure, the materials are compacted into solid sheets. These sheets are then crushed and screened to form fertilizer granules of the desired size. This process is commonly used for the production of fertilizers such as rare earth elements, ammonium bicarbonate, ammonium chloride, ammonium sulfate, and binary nitrogen-potassium fertilizers.

Process Features

Factors Affecting the Bulk Blending Process

- The particle size of the raw materials should vary, with an optimal range between 0.1 and 1 mm. If the particles are too fine (less than 0.1 mm), they contain too much air, which can reduce the density of the compacted sheets and increase vibrations during the compaction process. On the other hand, particles that are too large require more energy to crush, making it important to control the feed size carefully to optimize efficiency.

- The pressure used during compaction is affected by the hardness and plasticity of the raw materials. Materials such as potassium chloride, diammonium phosphate, and urea have good plasticity, making them easier to granulate. However, materials like potassium sulfate, ammonium sulfate, and phosphate rock powder have lower plasticity, making them more difficult to granulate. To achieve better results, adding an appropriate amount of binder can help improve the compaction process and the quality of the granules.

- The compaction granulation process eliminates the need for heating or adding moisture to the materials, which not only reduces energy consumption but also lowers investment costs. This makes it an ideal solution for heat-sensitive materials, such as ammonium bicarbonate and certain organic fertilizers.

- With a short production line and a system that is easy to operate, this fertilizer production method simplifies the entire process, making it ideal for automation and boosting overall production efficiency.

- With the compacted fertilizer production process, it is possible to produce fertilizers with a higher nutrient concentration than typical compound fertilizers. Additionally, the ability to easily add organic fertilizers and other nutrients makes it highly adaptable to different crop needs.

- The fertilizer production line is highly flexible, allowing for quick adjustments to product formulations. This is especially useful for small-batch production of specialized fertilizers, giving manufacturers the ability to respond to market demands with ease.

Other Fertilizer Production Lines

Contact us now

To Learn About Our Fertilizer Production Lines

Mobil/Whatsapp

086-17715506502

karen@yrcexport.cn