Customization of Overseas Compound Fertilizer Production Lines: Global Implementation Practice Driven by Technology

In the field of modern agricultural equipment, the customization capability of compound fertilizer production lines is a concentrated reflection of the technical strength and engineering experience of enterprises. The successful delivery of every cross-border project, from equipment adaptation in high temperature and high humidity environments in Vietnam to system energy efficiency optimization in tropical climates in Indonesia, is a precise coupling of mechanical design and localized requirements. This article deeply analyzes the core technological breakthroughs and engineering implementation logic in production line customization through four benchmark cases.

Vietnam 200,000 tons production line: equipment performance breakthrough in humid environments

Core challenge:

Vietnam’s average annual humidity is over 85%, resulting in a 30% increase in raw material agglomeration rate and affecting granulation efficiency.

Technical transformation plan:

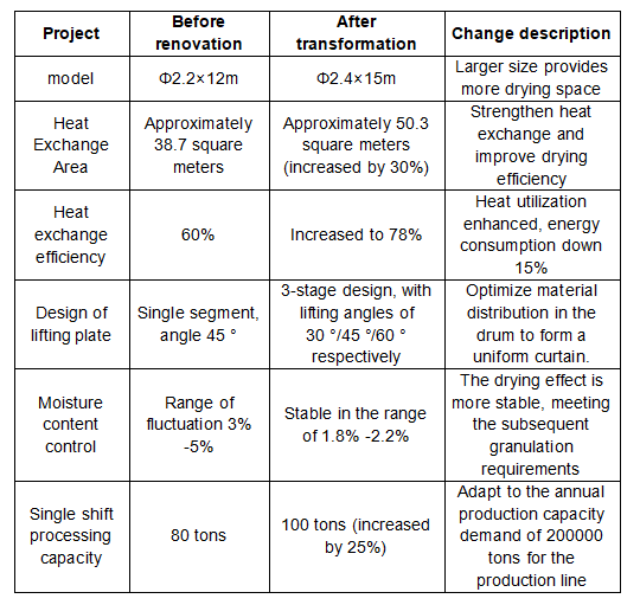

▪The drum dryer is upgraded to Φ2.4×15m, the heat exchange area increases by 30%, and the moisture content is stable at 1.8%-2.2%.

Image Example

▪15° inclined double screw unloading box, inner wall covered with PTFE coating, single shift operation is extended to 12 hours.

▪S49-1.2 type vibrating screen preconditioning, mixing uniformity deviation ≤±1%.

Engineering implementation:

180 days on-site service, completed foundation strengthening and ventilation renovation, and achieved a qualified granulation rate of 98.3% after 72 hours of trial operation.

Comparison table of parameters before and after the transformation of drum dryer

100,000 tons turnkey project: three-dimensional coordinated and fast delivery system

Project difficulty:

Deliver the entire process in 4 months, which is 40% lower than the industry standard.

Technological innovation points:

▪BIM+3D preliminary assembly, virtually solves 7 interference, increases installation efficiency by 50%.

▪WZ-10 gravity free mixer, with a mixing uniformity of 97%+and a cycle shortened to 4 minutes.

Engineering management:

Three thread collaboration, completed the lifting of 8 devices within 48 hours, and reached 82% of the design capacity within 3 days after VR training.

150,000 tons production line: modular design of fast switching system

Core requirement:

To meet the fertilizer needs of Southeast Asian economic crops and achieve rapid conversion of nitrogen, phosphorus, and potassium ratios.

Key technologies:

▪6 sets of Φ168mm metering spirals, formula switching is completed in 15 minutes, with an accuracy of ±0.5%.

▪316L stainless steel mixed liner, corrosion resistance is 3 times higher than 304.

Implementation period:

72 hours disclosure after contract signing, pipeline connection period reduced to 28 days.

Indonesia 100,000 tons NPK production line: Energy efficiency revolution of dual-machine systems

Climate challenge:

The daily temperature exceeds 35 ℃, and the cooling load of a single drying system exceeds 30%.

System optimization:

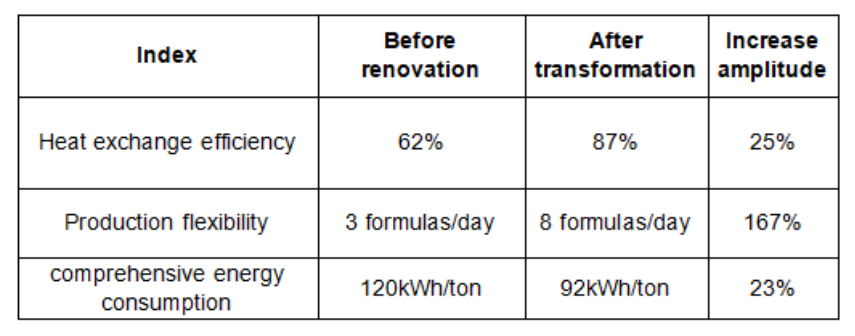

▪Parallel connection of dual Φ 1.8 × 15m dryers reduces natural gas consumption from 80m ³/ton to 65m ³/ton.

▪Independent temperature control, suitable for different moisture raw materials.

Operating data:

Summary

Choose us to make your compound fertilizer production without worries.As a powerful enterprise that has deeply cultivated the field of compound fertilizer production line customization, we have built three core technical advantages with the practical accumulation of many multinational projects to protect your production needs.

From the signing of a contract to the production line being put into production, we efficiently coordinate all links to enable you to achieve production profitability as soon as possible.Whether you are producing general fertilizers for food crops or special fertilizers for cash crops, you can flexibly adjust to meet the diversified market needs and improve your competitiveness in the industry.

By choosing us, you will not only get a high-quality composite fertilizer production line, but also a comprehensive production guarantee.