Discover the Ball Mill: "Almighty Warrior" in the field of industrial grinding

In modern industrial production systems, material grinding is the basis of many key processes. With a century of technological accumulation and continuous innovation, Ball Mills have become the core equipment in mining, building materials, chemical and other industries. Through unique mechanical principles and flexible parameter regulation, it builds a full-scene solution covering coarse grinding to ultra-fine grinding.

1. Core structure and working principle

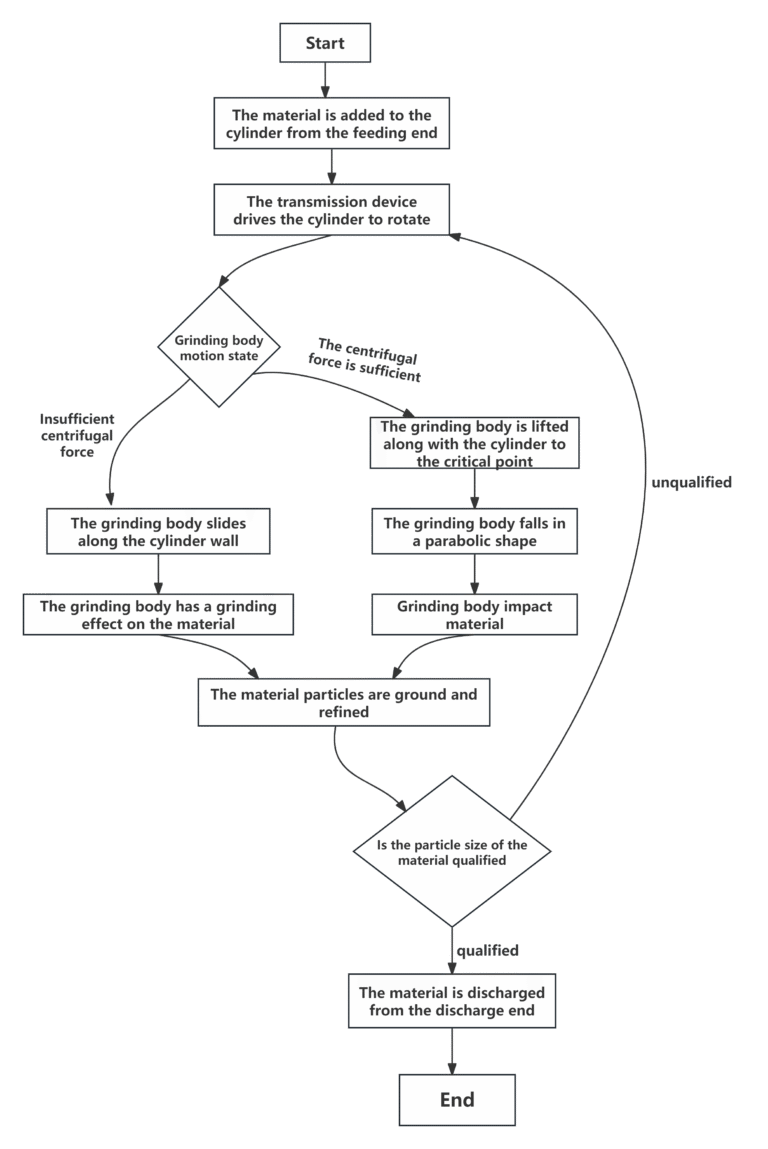

The ball mill consists of three core modules: cylinder, transmission system, and grinding medium. The cylindrical cylinder is made of high manganese steel or rubber lining, and is built-in steel balls, ceramic balls and other grinding bodies; the frequency converter drives the cylinder to rotate at 70%-85% of the critical speed through a reducer. During operation, the grinding body rises to the parabolic critical point with the cylinder and falls to impact and crush large-particle materials; at the same time, the sliding and rolling of the grinding body form a grinding effect, and the material is refined to the micron level.

Ball mill workflow diagram

Process adaptation is achieved through three factor regulation in production:

Speed adjustment: High speed strengthens impact, suitable for coarse crushing; low speed focuses on grinding, used for fine processing.

Media ratio: For hard materials such as quartz stone, large-diameter high-chromium steel balls are used; when treating coating pigments, small-particle zircon balls are used instead.

Fill rate optimization: Under normal working conditions, the filling rate of the grinding body remains 40%-50%, and the ultra-fine grinding scene can be increased to 65%.

2. All-field application matrix

(1) "Dissociation Hub" for Mining Ore Disposal

In the copper, iron and gold ore ore ore process, the ball mill undertakes the key grinding process. A large molybdenum ore uses a 5.5-meter-diameter overflow ball mill, and combines a grader to form a closed-circuit cycle, grinding the original ore to -200 mesh accounts for 75%, increasing the recovery rate of molybdenum concentrate by 8 percentage points, and the daily processing volume exceeds 12,000 tons.

(2) "Grinding Heart" in the cement industry

In the new dry cement production line, the ball mill is responsible for prep-grinding of raw materials and final cement grinding. The 4.2×13-meter specification equipment is combined with an efficient powder sorter. The output at the time of the table can reach 200 tons, and the specific surface area is controlled at 350-400㎡/kg, meeting the P.O 42.5 cement production standard. A certain building materials group reduces the electricity consumption of ton of cement by 12kWh by optimizing the steel ball grading.

(3) "Nanometre engine" for the development of new materials

In the field of lithium battery material preparation, a high-energy planetary ball mill rotates at a high speed of 300rpm, and with argon protection, the lithium iron phosphate precursor is ground to D50=1.8μm, with a particle size distribution Span value <0.6, significantly improving the battery cycle life. This process is 40% higher than the traditional stirring and grinding efficiency, and the metal impurity pollution rate is 70%.

3. New directions for technological iteration

Currently, the ball mill is upgrading along the path of intelligence, greening and efficient:

The intelligent operation and maintenance system integrates vibration, temperature and current sensors, predicts bearing failures through AI algorithms, reducing unplanned downtime by 60%;

The energy-saving structure adopts a hyperbolic cylinder design, reducing wind resistance by 15%, and the comprehensive energy consumption is reduced by 22% with a permanent magnet synchronous motor;

The environmentally friendly transformation is equipped with pulse bag dust removal and noise reduction lining, with dust emissions less than 10mg/m³ and the operating noise is controlled within 85dB.

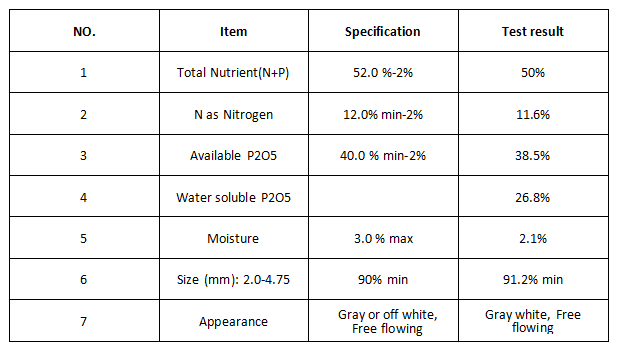

Comparison Table of Energy Consumption Before and After Upgrading Ball Mill Technology

From 10,000-ton mining behemoths to laboratory nanometre scale grinding equipment, ball mills respond to changing industrial needs with unchanging mechanical intelligence. With the integration of technologies such as 5G remote control and nanometre coating materials, this “industrial evergreen” will continue to revive in the field of high-end manufacturing.