Hammer roller crusher: a versatile player who innovates crushing technology

In the fields of ore processing, building materials production, the performance of crushing equipment directly affects production efficiency and product quality. With its unique technical architecture and excellent performance, hammer roller crusher has become a “strategic equipment” for enterprises to upgrade and produce, and is reshaping the crushing industry structure.

1. Amazing Broken Ratio: Break the efficiency shackles of multi-level brokenness

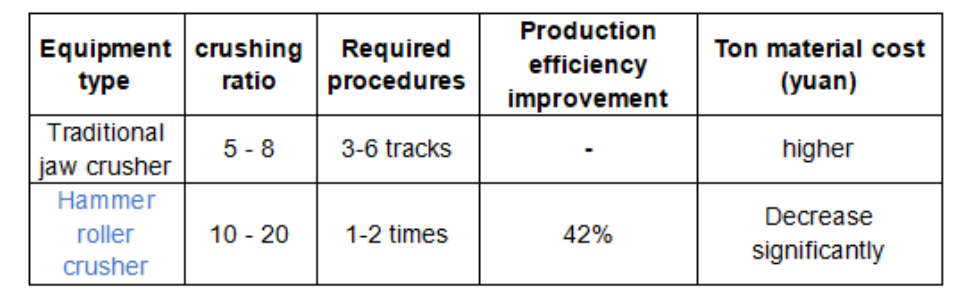

The Hammer roller crusher combines the impact kinetic energy of hammer crushing and the abrasive characteristics of roller crushing to build a “double-effect synergy” system. The high chromium alloy hammer head crushes the material at a linear speed of 60 – 80m/s, and then extrudes and grinds through a hydraulic roller set of 20 – 50MPa. Its crushing ratio is 10-20, which is more than 150% higher than that of traditional jaw crushers. A mine used it to simplify the 6 crushing processes into 2 treatments, increasing production efficiency by 42%,and reducing dust and material losses.

Comparison with traditional jaw crusher

2. Energy-saving pioneer: Redefining green crushing standards

Equipped with permanent magnet synchronous frequency converter motor and planetary gear transmission, the power transmission efficiency exceeds 98%; the Computational Fluid Dynamics-optimized spiral crushing cavity forms a “self-circulating eddy current”. Compared with traditional equipment, unit energy consumption is reduced by 27%, and annual carbon dioxide emissions are reduced by more than 300 tons. After a building materials group replaced 8 units of this equipment, it saved 12 million yuan in electricity bills and reduced noise by 15 decibels. It was certified as a provincial green factory.

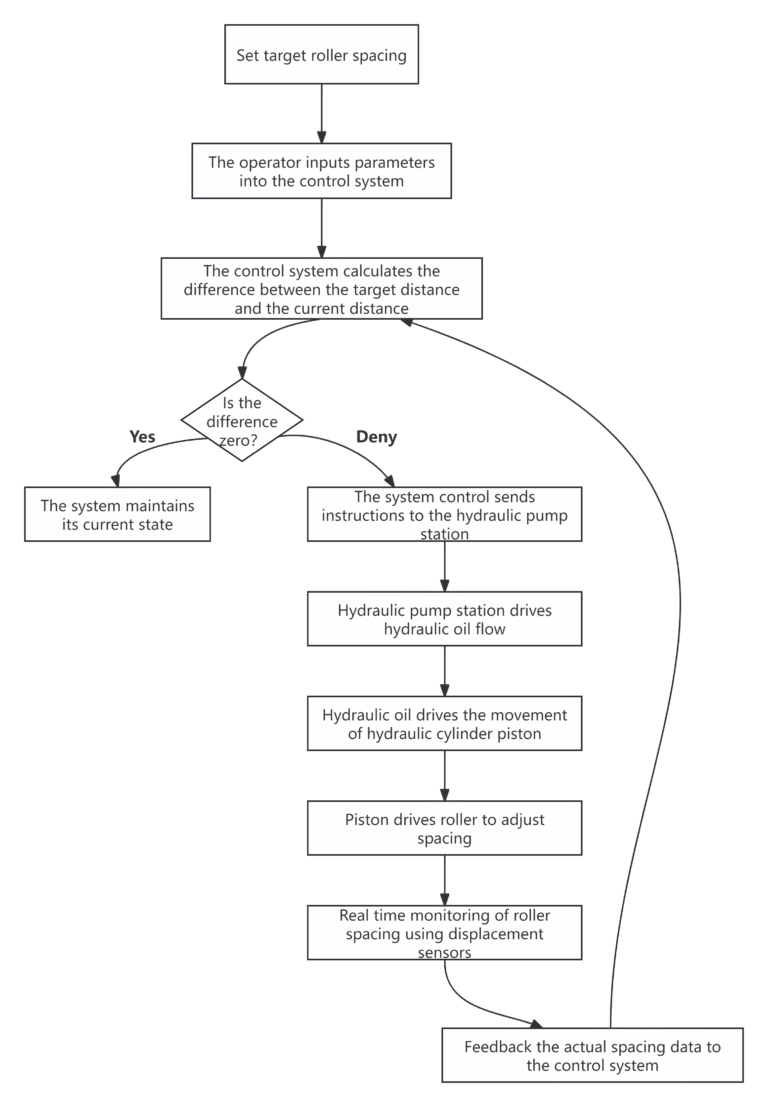

3. Accurate granularity control: unlock the password for high-end material processing

With “hardware fine adjustment + intelligent closed loop”, the hydraulic gap adjustment accuracy reaches ±0.1mm, and the laser particle size analyzer is linked to the PLC system to ensure that the particle size pass rate is above 99.5%. The silicon-carbon negative electrode material produced by a certain enterprise uses the particle size concentration (Span value) of 0.8, which is better than the average level of the industry 1.2, and enters the international high-end supply chain.

Workflow diagram of hydraulic automatic clearance system

4. High reliability and long life: build a solid line of defense for continuous production

The core components are military-grade standards, with hammer head hardness HRC65, and the thickness of the tungsten carbide wear-resistant layer of the roller is 25mm, and the wear resistance is 3 times improved. The quick-release structure reduces the replacement time of consumable parts from 8 hours to 1.5 hours. A certain open-pit coal mine equipment operated continuously for 9,200 hours, and the core components were only worn 3mm.

From efficiency, energy saving to accuracy and durability, hammer roller crushers redefine the value of crushing equipment with all-round advantages. With the integration of technology, it will open up broader space in new energy and other fields to promote high-quality development of manufacturing.