ROTARY DRUM GRANULATOR

In fertilizer production, rotary drum granulators are necessary to turning powdery materials into solid, uniform granules. This granulating equipment is commonly used for making compound fertilizers with different nutrient levels, from low to high concentrations. The process involves adding water, steam, or slurry into the drum along with the raw materials. As the drum rotates, the particles are mixed and pressed together, forming strong granules.

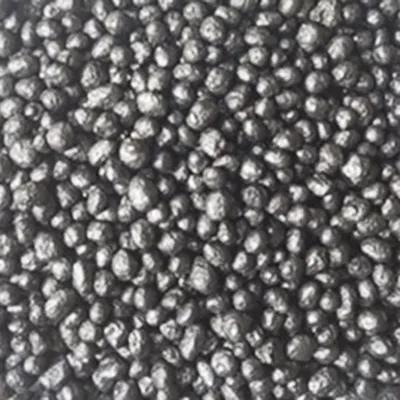

Granular Fertilizers

Features

- The inside of the drum is lined with special rubber plates that help with self-cleaning and prevent corrosion. For more durability, options like engineering plastic or stainless steel can be used as linings.

- The gear rings and support rollers are made from cast steel, which increases wear resistance and ensures the drum lasts longer, even during heavy use.

SPECIFICATIONS

| Drum size (m) | Drum | Production capacity (t/h) | Reducer | Motor | Dimensions (L×W×H) (mm) | Weight (t) | |||||

| Inner diameter (mm) | Length (mm) | Inclination (°) | Rev. (r/min) | Model | Ratio | Model | Power (kW) | ||||

| Ø0.8×3.2 | 800 | 3200 | 2.5 | 17 | 2.5 | JZQ350 | 15.75 | Y132M1-6 | 4 | 3800×1800×2000 | 5.5 |

| Ø1.2×3.5 | 1200 | 3500 | 2.5 | 18.07 | 3 | JZQ500 | 12.5 | Y160M-6 | 7.5 | 3960×3070×2129 | 7 |

| Ø1.4×4 | 1400 | 4000 | 2.5 | 15.05 | 5 | JZQ500 | 20.49 | Y160M-4 | 11 | 4400×2810×2600 | 8 |

| Ø1.5×5 | 1500 | 5000 | 2.5 | 12.6 | 6 | ZQ50C | 12.64 | Y180L-6 | 15 | 5400×2910×2800 | 10 |

| Ø1.6×6 | 1600 | 6000 | 2.5 | 12 | 7 | ZQ50C | 12.64 | Y180L-6 | 15 | 7700×3003×3216 | 11 |

| Ø1.8×6 | 1800 | 6000 | 2.5 | 11.5 | 8 | ZQ650 | 10.35 | Y180L-6 | 15 | 8000×3335×3350 | 16 |

| Ø1.8×8 | 1800 | 8000 | 2.5 | 11.5 | 10 | ZQ650 | 10.35 | Y180L-6 | 15 | 10000×3380×3350 | 18 |

| Ø2.0×7 | 2000 | 7000 | 2.5 | 10.8 | 14 | ZQ650 | 10.35 | Y225M-6 | 30 | 11000×3900×3750 | 25 |

| Ø2.2×8 | 2200 | 8000 | 2.5 | 10.85 | 20 | ZQ650 | 12.64 | Y250M-6 | 37 | 9500×4410×3900 | 29 |

| Ø2.4×10 | 2400 | 10000 | 2.5 | 9.6 | 25 | ZL75 | 20 | Y250M-4 | 55 | 11600×4636×4955 | 42 |

| Ø2.6×10 | 2600 | 10000 | 2.5 | 9.17 | 30 | ZL75 | 12.5 | Y315M-6 | 90 | 12200×4850×4262 | 52 |

| Ø2.8×10 | 2800 | 10000 | 2 | 8.35 | 35 | ZLY315 | 14 | Y280M-6 | 90 | 12000×5300×5200 | 60 |

| Ø2.9×10 | 2900 | 6000 | 1.8 | 9.46 | 40 | ZL85 | 14 | Y315M2-6 | 132 | 9000×5400×5800 | 68 |

| Ø3.0×9 | 3000 | 9000 | 1.8 | 9.06 | 45 | ZLY355 | 20 | Y315L1-4 | 160 | 11000×6000×5800 | 70 |

| Ø3.2×1C | 3200 | 1000C | 2.5 | 8.54 | 50 | ZL100 | 20 | Y315L1-4 | 160 | 12100×5050×5800 | 80 |

| Ø3.3×9 | 3300 | 9000 | 2.5 | 9.14 | 55 | ZLY400 | 20 | Y315L2-4 | 200 | 12500×6689×6399 | 85 |

| Ø3.5×8 | 3500 | 8000 | 2.5 | 9.25 | 56 | ZLY400 | 20 | Y315L2-4 | 200 | 10000×6800×7000 | 93 |

| Ø4.1×9 | 4100 | 9000 | 2.5 | 8.1 | 13 | ZLY400 | 20 | YKK2002-4 | 280 | 10600×7200×7300 | 130 |

FAQ

What is a Fertilizer Granulator?

Fertilizer granulators are essential machines in the fertilizer manufacturing industry, used to convert organic and compound fertilizers into consistent granule sizes. These granules ensure easier application and better nutrient distribution for crops.

What are the common methods for fertilizer granulation?

In the fertilizer industry, the two most common granulation techniques are dry granulation and wet granulation. The choice between these methods depends on the type of fertilizer and the desired characteristics of the final product, with each offering its own advantages in terms of efficiency and granule quality.

Related Products

Contact us now

To Learn About Our Fertilizer Production Lines

Mobil/Whatsapp

086-17715506502

karen@yrcexport.cn